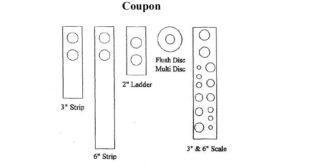

Two-inch System HC Series Coupon Probes

HC Series Probes are used in conjunction with the TRISEAL High Pressure Access Fitting Assembly

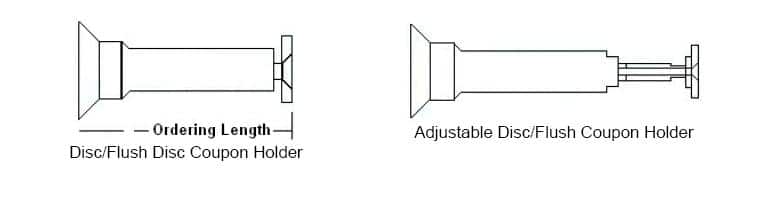

The Coupon Probe or holder is attached to the Solid Plug Assembly by means of an O.D. left handed thread connection and also retains the primary packing. Disc Coupon Probes are primarily intended for use in areas where pigging operations prohibit the use of projecting style probes. Additional advantages are the lack of requirement to orient the coupon relative to the flow direction and a greater exposed surface area at the pipe wall. Coupon Probes are manufactured in 316 SS and are available in lengths from 2.50 inches to 36 inches

Fixed or adjustable Disc / Flush disc

To calculate the correct ordering length use the following formula.

ORDERING LENGTH =P + W + 2.50 inches

where P = Penetration required in pipe

W = Wall thickness of pipe

Note: Formula is based upon a standard access fitting height of 5.25 inches and 0.0625 weld gap per ANSI B31.1.1973

Corrosion Coupons can be supplied in most alloys and are complete with Coupon Mounting Kit

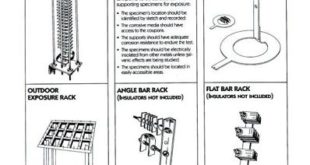

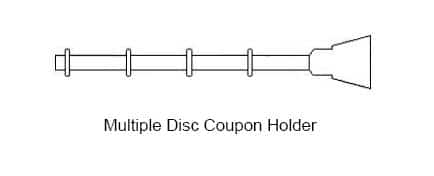

Multiple Disc Coupon monitoring

Multiple Disc Coupon monitoring is suitable for pipes with I.D. greater than 6.00 inches. Multiple Disc Monitoring permits coupons to be placed at a specific level in multi phase or stratified flow. The coupons are insulated from the probe rod by Nitrile O rings. Delrin or Nylon Spacers are used to provide insulation between coupons. Materials of construction satisfy the requirements of Nace MR-01-75

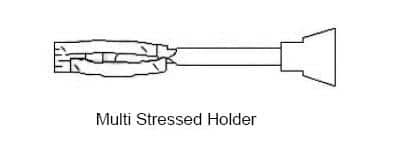

Applied Stress Coupons

Applied Stress Coupons are 152mm (6 inches) long, 22.3 mm (0.875 inches) wide, 3.18mm (0.125 inches) thick. An insulated adjusting screw located on the coupon mid-point applies stress to the coupon

NOTE: Applied stress coupons have been stamped on the end because this is the lowest stress area and cracking is not expected to be initiated by the identification mark

Applied stress is determined from the number of adjusting screw turns or bending deflection. The coupons are first stressed and then installed in the line. The time required for cracks to develop is determined by pulling coupons at regular intervals, usually 24 hours to 30 days. Test duration will vary with the stress level applied to the coupon. The time to crack may then be used as a measure of stress corrosion resistance

Test start time begins when stress is applied and the stressed coupon is exposed to the corrosive environment, whichever occurs later. The coupon is considered to have failed when cracks appear. The cracks may be detected by optical, mechanical or electrical means

Cracking time is the elapsed time from test start until the appearance of cracks

Formula for Applied Stress Coupons

S = 6Ety/H

Where:

S = maximum tensile stress

E = modulus of elasticity

t = thickness of coupon

y = maximum deflection

The formula is for longitudinal stress in the outer fibres of the coupon, below the elastic limit of the material. At stress above the elastic limit, but below the yield strength at 0.2% error results. The formula must not be used above the yield strength of the material

NOTE: The formula is based on small deflections i.e. y/H is less than 0.1

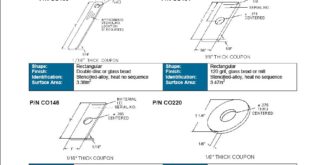

HIGH PRESSURE COUPON HOLDER ORDERING INFORMATION CHART

Coupons are supplied ready for use

C1018 coupons are stamped with a sequence number. All alloy coupons are

• Stamped with the alloy and sequence number

• Coupons are pre-weighed and individually packaged in a Data Front VCI bag

• Coupons are supplied with a mill test report and a weight log chart

• Coupons are cleaned of all contaminants and have a sand blasted finish

• Nylon insulators are mounted into coupons

Petro Parda Co. Enginering, supply and construction of oil, gas & waste water treatment

Petro Parda Co. Enginering, supply and construction of oil, gas & waste water treatment